In the rapidly evolving landscape of manufacturing and design, Aluminum Extrusion stands out as a game-changing process that offers a plethora of advantages for various projects. As industry expert John Smith, a leading authority on aluminum manufacturing, aptly puts it, "Aluminum extrusion not only enhances the structural integrity of products but also provides unmatched versatility in design." This statement underscores the core benefits that have made aluminum extrusion a preferred choice for architects, engineers, and manufacturers alike.

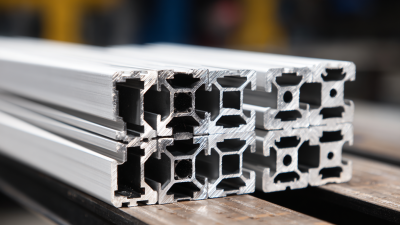

The process of aluminum extrusion involves forcing aluminum alloy through a shaped die, resulting in highly customizable profiles that meet specific project requirements. This flexibility allows designers to push the boundaries of creativity while maintaining the strength and durability needed in modern applications. With its lightweight nature, resistance to corrosion, and excellent thermal conductivity, aluminum extrusion is increasingly being utilized in construction, automotive, and consumer goods sectors.

Moreover, the environmental benefits of aluminum extrusion cannot be overlooked. It is a sustainable option due to the recyclability of aluminum and the energy efficiency of the production process. As companies look for ways to innovate while minimizing their carbon footprint, aluminum extrusion presents an ideal solution. In conclusion, leveraging the advantages of aluminum extrusion in your next project can lead to superior outcomes that are both efficient and environmentally friendly.

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy into a desired cross-sectional profile. This technique is widely utilized across various industries due to its versatility and efficiency. According to a report by The Aluminum Association, the aluminum extrusion market is projected to reach $40 billion by 2025, driven by increasing demand in sectors such as construction, automotive, and aerospace. The lightweight nature of aluminum, combined with its strength and resistance to corrosion, makes it an ideal choice for applications ranging from window frames to complex aircraft components.

The applications of aluminum extrusion are vast, making it a critical component in modern manufacturing. For instance, in the construction industry, extruded aluminum is frequently used for architectural details, curtain walls, and structural supports, providing not only durability but also aesthetic appeal. In the automotive sector, lightweight aluminum extrusions contribute to fuel efficiency by reducing overall vehicle weight, which is essential in meeting stringent environmental regulations. Furthermore, a study by Grand View Research highlights that the automotive segment of the aluminum extrusion market is expected to grow at a CAGR of 6.5% from 2021 to 2028, underscoring the material's growing importance. This demonstrates how aluminum extrusion not only enhances performance but also supports sustainability efforts in various industries.

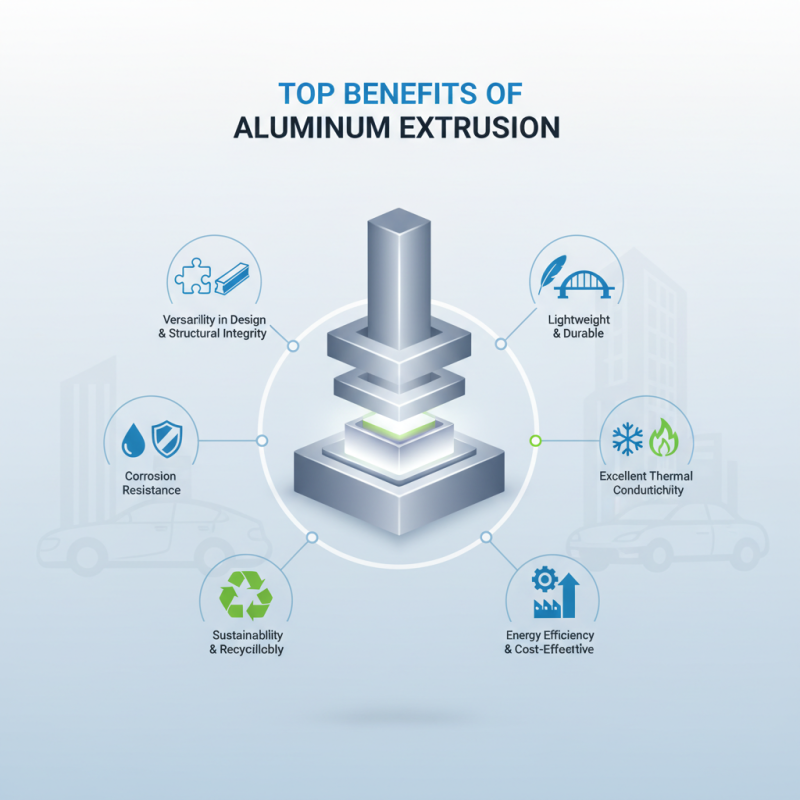

Aluminum extrusion is gaining popularity in the manufacturing sector due to its high versatility and efficiency. One of the key advantages of using aluminum extrusion is its ability to create complex shapes with remarkable structural integrity. According to a report by the Aluminum Association, extruded aluminum can deliver up to 40% more strength compared to steel at a significantly reduced weight. This property makes it the preferred choice for industries ranging from aerospace to construction, where reducing overall weight without compromising performance is crucial.

Another critical benefit lies in the sustainable nature of aluminum. The recycling rates for aluminum exceed 90%, and the process of recycling uses only 5% of the energy required to produce new aluminum. This not only helps manufacturers adhere to strict environmental standards but also contributes to cost savings in material expenses. A study by the International Aluminum Institute highlights that utilizing aluminum extrusion can lead to a 75% reduction in energy consumption for certain applications. With these advantages, aluminum extrusion stands out as a pivotal element for engineers and designers aiming for both efficiency and sustainability in their projects.

Aluminum extrusion offers unparalleled design flexibility and creativity, making it an ideal choice for a range of projects across various industries. According to the Aluminum Association, extruded aluminum can be customized to meet specific dimensional requirements and can accommodate complex designs that might be challenging with other materials. This capability allows designers and engineers to explore innovative shapes and configurations, pushing the boundaries of traditional design. For instance, the ability to create intricate profiles not only enhances aesthetic appeal but can also lead to weight savings, resulting in structures that are both visually stunning and efficient.

Moreover, aluminum's lightweight nature, combined with its strength and durability, facilitates an easier and more flexible approach to design. A report from the National Aluminum Association indicates that aluminum's flexibility allows for seamless integration with other materials, enabling designers to create hybrid solutions that enhance functionality. The thermal and electrical conductivity of aluminum further expands its application in designs requiring specific performance characteristics, from architectural elements to automotive components. The adaptability of aluminum extrusion empowers designers to innovate, ultimately leading to products that meet modern consumer demands while optimizing production processes.

This chart illustrates the key benefits of aluminum extrusion, with scores ranging from 1 to 10. Design flexibility stands out as the top benefit, closely followed by durability and corrosion resistance, making aluminum extrusion a preferred choice for innovative projects.

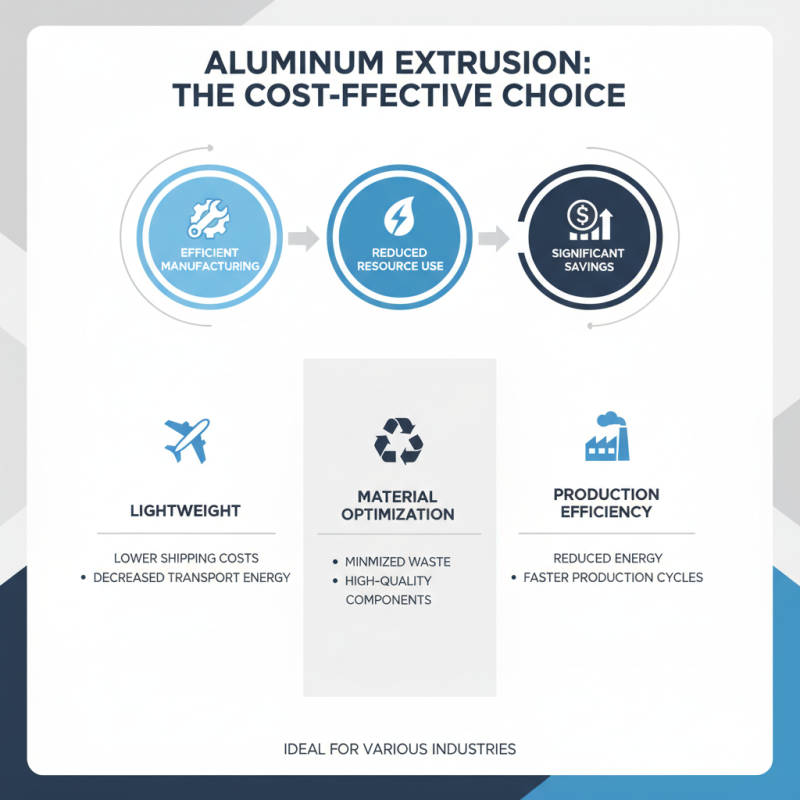

When evaluating project management strategies, cost-effectiveness often sits at the forefront of decision-making. Aluminum extrusion provides a compelling case in point, thanks to its ability to yield high-quality components while effectively managing resources. The lightweight nature of aluminum allows for lower shipping costs, reduced energy consumption during manufacturing, and decreased overall material waste. This translates to significant savings on both production and transportation fronts, making it an ideal choice for various industries.

**Tips:** When considering aluminum extrusion for your next project, always compare the lifecycle costs of materials. While the initial investment may vary, look at the long-term savings in maintenance and durability, as aluminum doesn’t rust and requires less upkeep compared to other materials.

Moreover, aluminum extrusion facilitates greater design flexibility, allowing engineers and architects to innovate without being burdened by weight limitations. This adaptability can lead to more efficient designs, further driving down costs associated with labor and materials. As projects evolve, the ease of altering designs without extensive retooling enables teams to stay on budget and meet tight deadlines.

**Tips:** Utilize CAD software in the early stages of design to explore various configurations of aluminum components. This can save time and resources while helping to identify the most cost-effective solutions before entering the production phase.

Aluminum extrusion offers numerous sustainability benefits that make it an excellent choice for projects aiming to reduce environmental impact. One of the primary advantages is the material's recyclability. Aluminum can be recycled indefinitely without degrading its properties, which significantly reduces the need for raw material extraction and energy consumption associated with mining and processing. By choosing aluminum extrusion, projects can contribute to a circular economy, minimizing waste and promoting resource efficiency.

Another aspect of aluminum's sustainability is its lightweight nature, which leads to lower transportation energy costs. The reduced weight not only makes installation easier but also means lower fuel consumption during transit, further decreasing the project's carbon footprint. Additionally, aluminum's durability and resistance to corrosion extend the lifespan of structures, reducing the need for replacements and repairs, which translates to less waste and resource use over time. Emphasizing these sustainable features can significantly enhance the appeal of any project while supporting environmental responsibility.