Aluminum extrusion has transformed modern industries. With its versatility, it shapes aluminum into intricate designs for various applications. Renowned expert Dr. Emily Carter emphasizes, "Aluminum extrusion is a key process driving innovation in manufacturing."

This manufacturing method offers numerous benefits. Lightweight yet strong, extruded aluminum enhances product performance. Moreover, it allows for complex shapes that meet specific needs. Industries like automotive and construction extensively use aluminum components. They appreciate its cost-effectiveness and sustainability.

However, challenges exist. Not every design can be efficiently produced through aluminum extrusion. Some applications may still require traditional methods. Companies must weigh these considerations. The process can sometimes lead to quality inconsistencies if not monitored properly. As industries evolve, understanding aluminum extrusion’s full potential is essential for continued innovation.

Aluminum extrusion is revolutionizing lightweight construction materials. Its versatility makes it perfect for various applications. Industries are adopting aluminum for its strength-to-weight ratio. This feature is crucial in reducing overall structural weight while maintaining durability.

In lightweight construction, every gram matters. Aluminum extrusions can simplify designs and reduce the need for heavy reinforcements. However, not every assembly benefits equally; analysis is key. Some projects might overlook potential downsides like corrosion if proper coatings are not used.

Cost considerations can also pose a challenge. While aluminum can be more expensive than traditional materials, the long-term savings on transportation and assembly may compensate. It's a delicate balance between upfront costs and eventual benefits. Thoughtful planning will enhance the advantages of aluminum extrusion in modern construction.

This chart illustrates the top benefits of aluminum extrusion in lightweight construction materials, highlighting factors such as weight savings, cost efficiency, corrosion resistance, and ease of fabrication.

Aluminum extrusion offers remarkable cost-effectiveness in mass production. This process allows manufacturers to create complex shapes without excessive waste. The efficient use of materials means lower raw material costs. Additionally, production times can be significantly reduced, leading to faster delivery. This speed is crucial in today’s competitive market.

Using aluminum extrusions can streamline manufacturing processes. The consistency of extruded products enhances quality control. However, achieving perfect uniformity can be challenging. Sometimes, slight variations in the extrusion process lead to imperfect dimensions. Such imperfections may require adjustments, potentially increasing costs.

Moreover, tooling costs may vary. Initial investments in molds can be high, but the long-term savings are notable. For instance, higher production runs help amortize these costs. Yet, businesses must consider their production scale carefully. Balancing initial costs with expected output is essential for success.

| Benefit | Description | Cost-Effectiveness |

|---|---|---|

| Lightweight | Aluminum is significantly lighter than steel, reducing transportation costs. | Lower shipping costs when large quantities are produced. |

| Durability | High resistance to corrosion and wear, enhancing product lifespan. | Reduced maintenance and replacement costs over time. |

| Versatility | Can be shaped into complex designs for various applications. | Flexibility in product design can lead to better market fit. |

| Recyclability | Aluminum is 100% recyclable without loss of properties. | Lower raw material costs from recycled inputs. |

| Aesthetic Appeal | Can be finished in various styles for design flexibility. | Enhanced product attractiveness can lead to higher sales. |

| Thermal Conductivity | Excellent conductor of heat, useful in thermal applications. | Improved energy efficiency in heating/cooling systems. |

| Electrical Conductivity | Good conductor of electricity, suitable for electrical applications. | Cost savings in electrical transmission systems. |

| High Strength-to-Weight Ratio | Strong yet lightweight, ideal for structural applications. | Minimized material usage without sacrificing strength. |

| Cost-Effective Manufacturing | Efficient mass production capabilities reduce overall costs. | Lower per-unit costs in high-volume production. |

| Quick Turnaround Times | Faster production from raw material to finished product. | Reduced lead times improve responsiveness to market demands. |

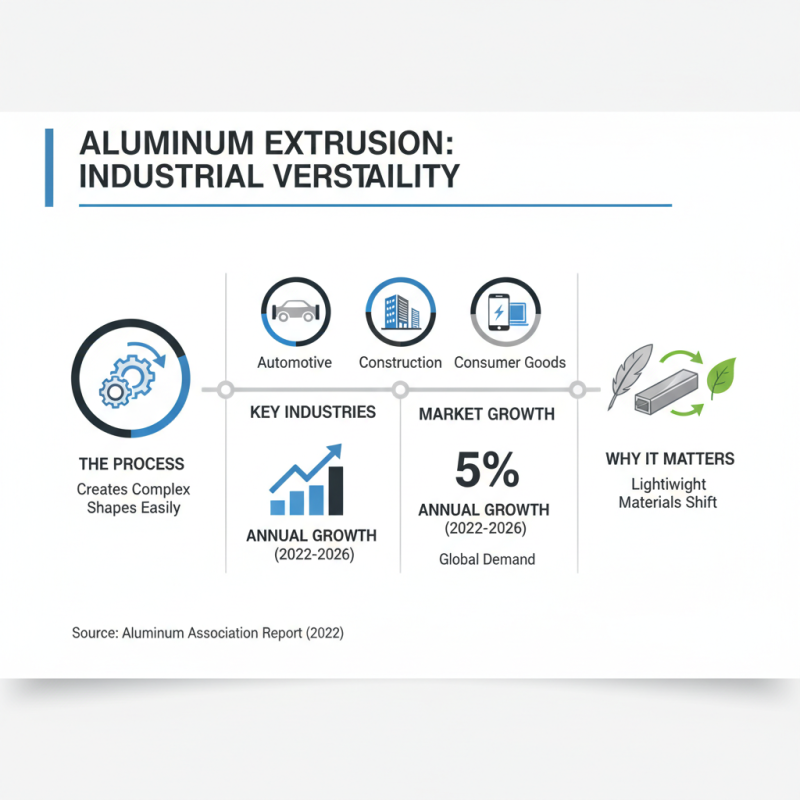

Aluminum extrusion has become a popular choice for various industrial applications due to its versatility. This process allows manufacturers to create complex shapes with ease. Industries such as automotive, construction, and consumer goods benefit immensely. According to a report by the Aluminum Association, the global demand for aluminum extrusions will grow by 5% annually through 2026. This reflects a strong market shift toward lightweight materials.

In the automotive industry, aluminum extrusions are used for lightweight frames and components. These parts enhance fuel efficiency by reducing vehicle weight. A study by the Department of Energy indicates that reducing weight by 10% can improve fuel economy by up to 7%. However, challenges remain. Not all manufacturers are equipped to handle the specific properties of aluminum alloys effectively. This can lead to quality inconsistencies in products.

Another critical area is construction. Aluminum extrusions are used in window frames, roofing, and structural supports. Their resistance to corrosion makes them ideal for various environments. However, builders sometimes underestimate the importance of alloy selection. Incorrect choices can lead to long-term durability issues. Emphasizing ongoing education and research in materials science is essential for maximizing the benefits of aluminum extrusion across industries.

Aluminum products stand out for their durability and corrosion resistance. Industries often choose aluminum due to these qualities. Products manufactured from aluminum can withstand harsh environments. They resist oxidation, ensuring they last longer than many alternatives. In sectors like construction and automotive, this trait is crucial.

Corrosion can lead to costly repairs and replacements. Aluminum's surface naturally forms a protective oxide layer. This layer shields it from the elements. Even in marine applications, aluminum shows impressive resilience. However, not all aluminum is created equal. The grade and treatment of the aluminum affect its performance.

Improper usage may lead to suboptimal results. Some industries underestimate the importance of quality. When aluminum is thinly extruded, it may not hold up well. This can result in structural concerns over time. It’s vital for manufacturers to ensure quality control and proper handling. Not paying attention might lead to failures. So, while aluminum offers durability, the execution makes all the difference.

Aluminum extrusion is gaining attention in modern manufacturing for its sustainability benefits. This process creates complex shapes without much waste. According to the Aluminum Association, extruding one ton of aluminum generates less than 10% of the waste compared to other materials. This efficiency is crucial as industries strive to minimize their environmental footprint.

Recycling aluminum is another key advantage. The recycling process saves around 95% of the energy needed to produce new aluminum from ore. In 2020, the global aluminum recycling rate reached approximately 75%. This is a significant improvement, yet there’s always room for growth. Many manufacturers still overlook the potential of refurbished materials, which could enhance sustainability efforts further.

Moreover, using aluminum helps create lightweight products that reduce transportation emissions. The lightweight nature of aluminum can lead to energy savings of up to 30% in vehicles. However, not all manufacturers are fully utilizing these potential savings. The need for innovation remains strong. More companies should explore how to utilize aluminum extrusion effectively to enhance sustainable practices while facing the challenge of integrating these methods into existing production lines.