In the rapidly evolving landscape of modern design, "Extruded Aluminum Enclosure Profiles" have emerged as a pivotal solution for engineers and designers seeking to enhance functionality and aesthetics. According to a recent market report from Smithers, the demand for aluminum profiles is projected to grow at a compound annual growth rate (CAGR) of 4.3% through 2027, driven by their lightweight, corrosion-resistant properties, and versatility in various applications, from electronics housings to architectural features. Furthermore, the use of extruded aluminum in enclosures is particularly advantageous due to its ability to offer thermal management and structural integrity across diverse environments. This trend underscores the growing recognition of how innovative design choices can lead to improved product performance and sustainability, prompting a deeper exploration into the benefits and applications of these profiles in contemporary design practices.

Extruded aluminum enclosure profiles play a pivotal role in eco-friendly design solutions by offering a combination of durability, lightweight properties, and recyclability. Unlike traditional materials, aluminum can be easily shaped through extrusion processes, reducing waste and enhancing efficiency. This innovation not only leads to lower energy consumption during manufacturing but also provides a sustainable option for modern designs, appealing to environmentally-conscious consumers and businesses alike.

Moreover, the longevity of extruded aluminum means that products made from this material require less frequent replacement, further minimizing environmental impact. Its resistance to corrosion and various weather conditions makes it an ideal choice for outdoor applications, ensuring that structures remain intact and functional for years. As industries increasingly shift toward sustainable practices, the adoption of extruded aluminum enclosure profiles demonstrates a commitment to reducing carbon footprints while maintaining high standards of design and functionality.

| Dimension | Value | Benefit |

|---|---|---|

| Weight | Lightweight | Easier handling and installation |

| Durability | High resistance to corrosion | Longer lifespan and lower maintenance costs |

| Recyclability | 100% recyclable | Supports eco-friendly practices |

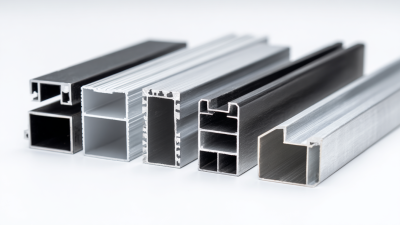

| Customization | Variety of shapes and sizes | Functional and aesthetic flexibility |

| Thermal conductivity | Excellent thermal properties | Improved energy efficiency in design |

| Aesthetic appeal | Modern and sleek finish | Enhances overall design quality |

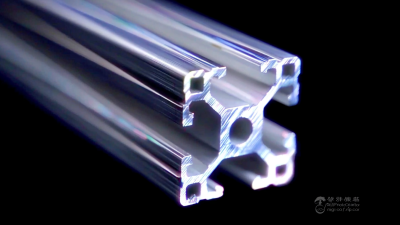

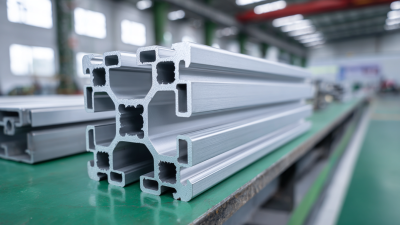

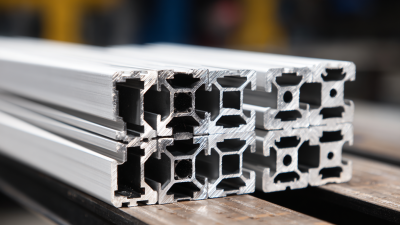

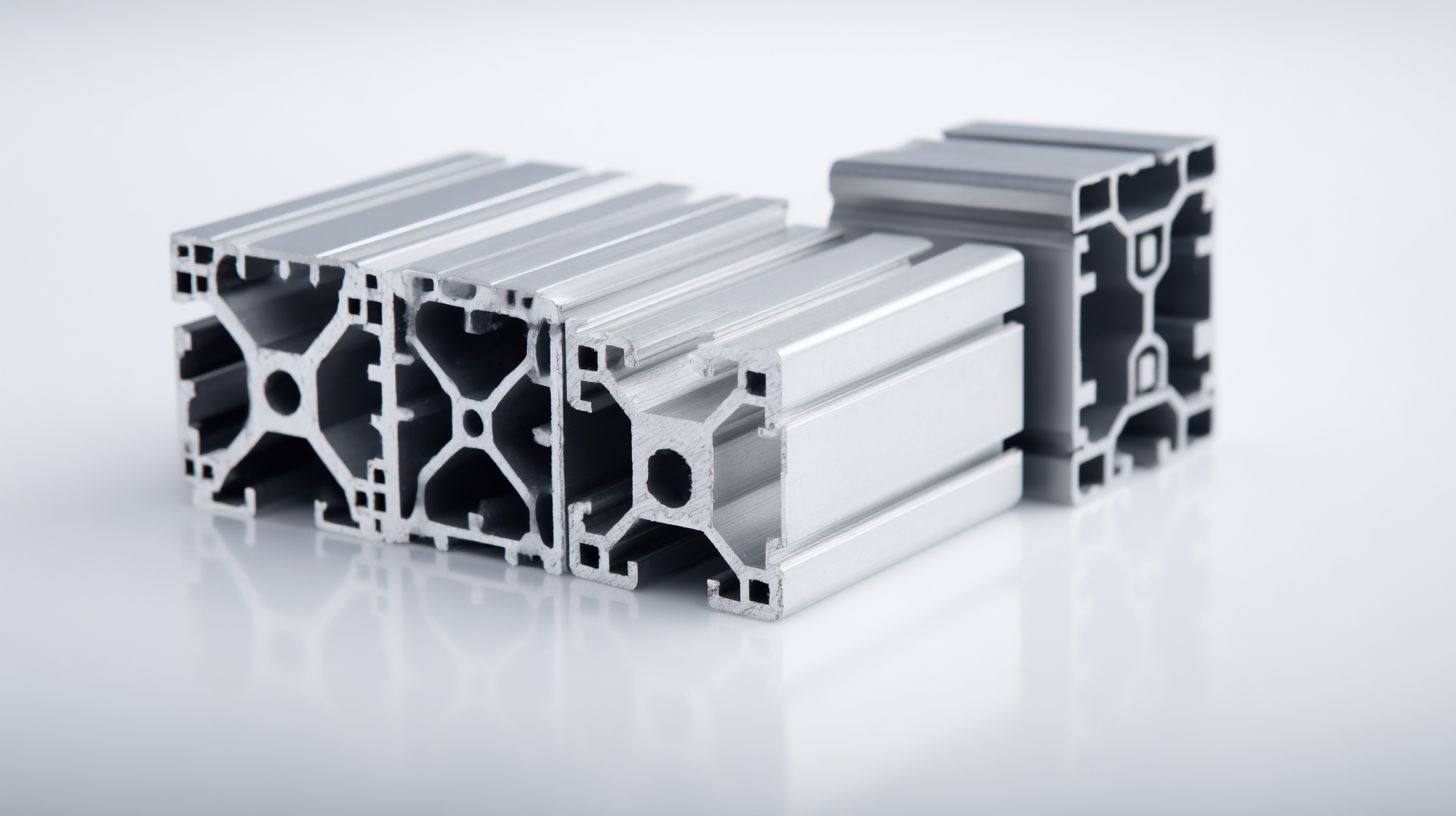

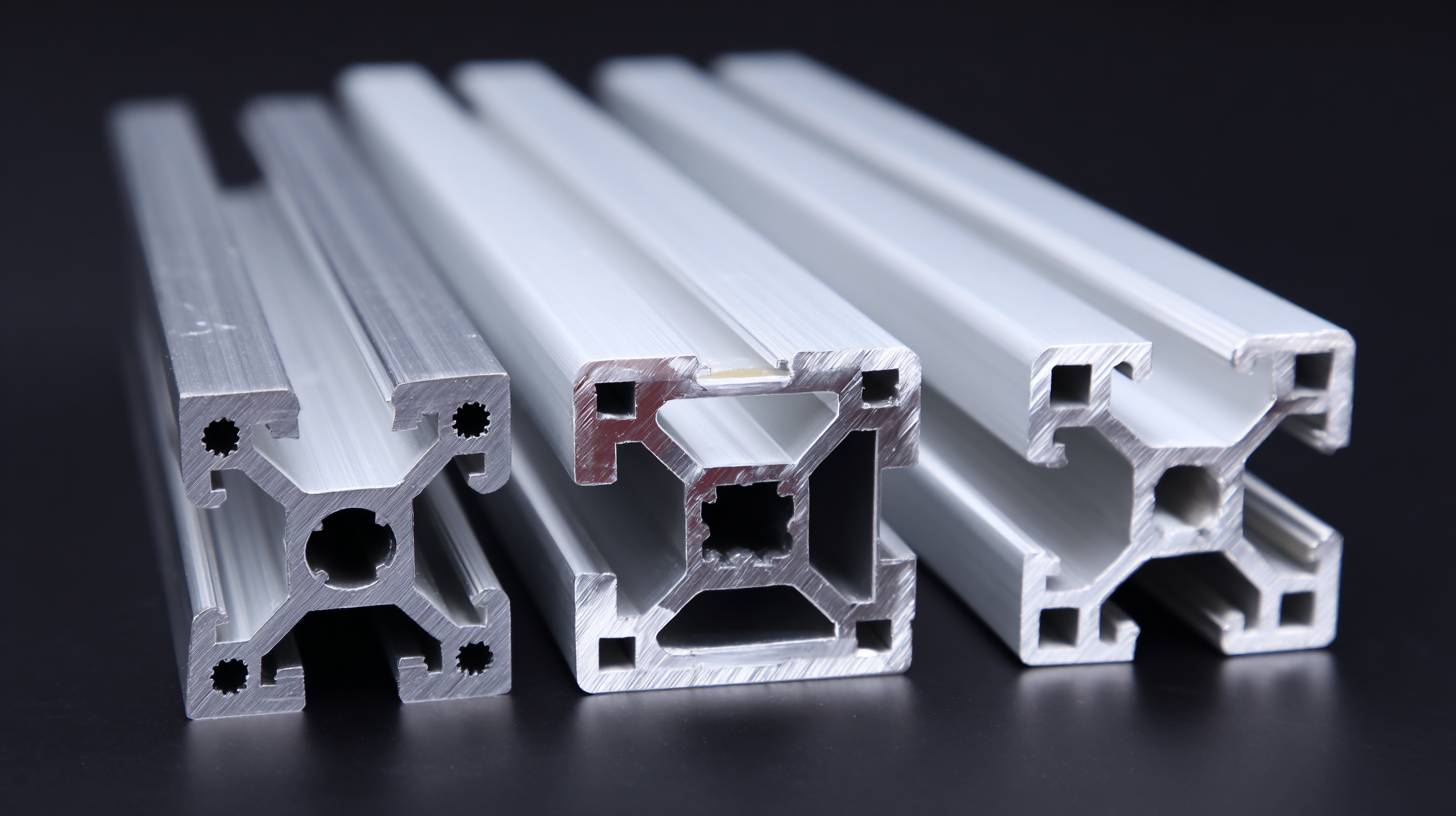

Extruded aluminum profiles have become increasingly popular in modern design due to their exceptional versatility. These profiles can be customized to meet a variety of specifications, making them suitable for numerous applications across different industries. Whether used in the construction of sleek architectural facades, innovative furniture designs, or complex machinery frames, extruded aluminum offers unmatched adaptability. Their lightweight yet strong nature allows designers to create intricate shapes and structures without compromising on strength or stability.

In addition to aesthetics, extruded aluminum profiles provide practical benefits that enhance performance and efficiency. They are resistant to corrosion and require minimal maintenance, which makes them ideal for outdoor applications and environments exposed to the elements. Moreover, their ease of fabrication and ability to integrate with other materials allow for seamless incorporation into modern manufacturing processes. From automotive components to consumer electronics, the multifunctionality and reliability of extruded aluminum profiles pave the way for innovative designs that are not only visually appealing but also inherently practical.

Customizable aluminum enclosures have emerged as a pivotal element in modern design, seamlessly blending aesthetics with functionality. These extruded profiles allow designers to create visually appealing products that meet specific project requirements. With a variety of finishes, colors, and textures available, aluminum enclosures can enhance the visual appeal of any application, from consumer electronics to architectural elements. The customizable nature ensures that each enclosure not only fits its operational needs but also aligns with brand identity, providing an overall cohesive look.

Customizable aluminum enclosures have emerged as a pivotal element in modern design, seamlessly blending aesthetics with functionality. These extruded profiles allow designers to create visually appealing products that meet specific project requirements. With a variety of finishes, colors, and textures available, aluminum enclosures can enhance the visual appeal of any application, from consumer electronics to architectural elements. The customizable nature ensures that each enclosure not only fits its operational needs but also aligns with brand identity, providing an overall cohesive look.

Moreover, the functional advantages of aluminum enclosures cannot be overlooked. Their lightweight yet robust structure makes them ideal for various applications, ensuring durability without compromising on ease of installation. The versatility of aluminum also allows for intricate designs that can accommodate various electrical and mechanical components. Enhanced features like thermal management, waterproofing, and additional mounting options further increase their applicability across industries, making customizable aluminum enclosures an essential tool for designers aiming to elevate both the functionality and aesthetic appeal of their projects.

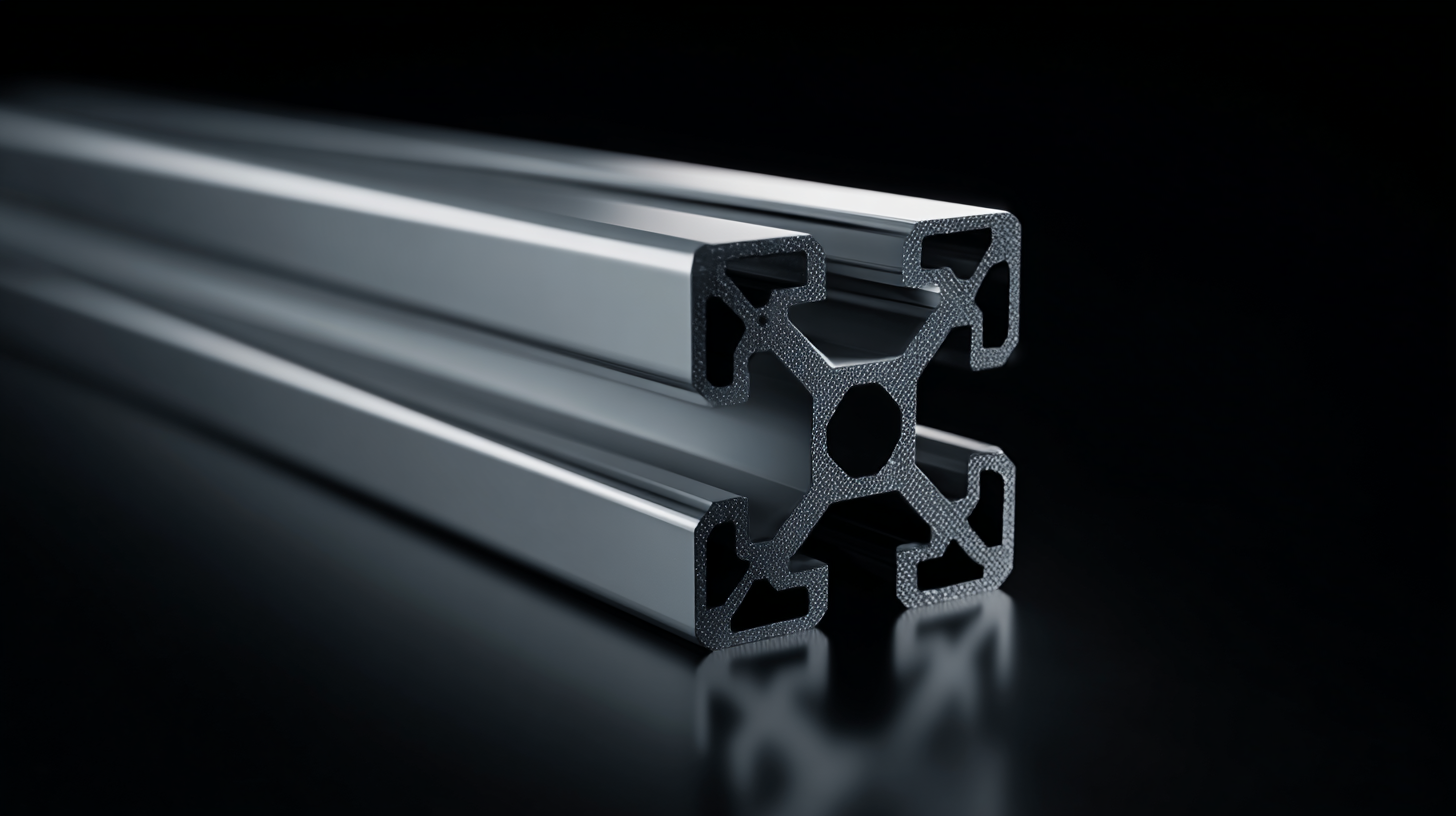

When evaluating design efficiency, extruded aluminum profiles stand out when compared to other materials such as plastic and steel. Aluminum's lightweight nature significantly reduces transportation costs and simplifies installation processes. Unlike heavier alternatives, aluminum allows for more intricate designs without compromising structural integrity, enabling architects and designers to push the limits of creativity while maintaining functionality.

Moreover, aluminum's inherent properties contribute to its superior performance in various applications. It boasts excellent thermal conductivity, which is crucial in electronic enclosures where heat dissipation is vital. Additionally, aluminum is resistant to corrosion, unlike many metals, ensuring longevity and reliability in both indoor and outdoor settings. While plastics may offer versatility in molding complex shapes, they often fall short in durability and heat resistance when compared to aluminum. Steel, while strong, cannot compete with aluminum in terms of weight and ease of fabrication.

Thus, as modern design increasingly demands efficiency and sustainability, extruded aluminum profiles lead the charge, combining performance with aesthetic appeal.

The advancements in extruded aluminum profile technologies are shaping the future of modern design through increased versatility and sustainability. According to a recent market report by Allied Market Research, the global aluminum extrusion market is projected to reach $112.3 billion by 2026, with a compound annual growth rate (CAGR) of 5.2%. This growth is driven by innovations in extrusion techniques, which allow for more complex profiles and improved material performance. These advancements enable designers to create lightweight yet durable enclosures that meet the rigorous demands of various applications, from electronics to architecture.

Moreover, the integration of smart technologies into aluminum extrusion processes is another trend revolutionizing the industry. Techniques such as 3D modeling and simulation are now commonplace, allowing manufacturers to optimize designs before production, ultimately reducing waste and energy consumption. A report by Technavio highlights that the adoption of automated extrusion processes can increase efficiency by up to 30%, catering to the rising demand for customized solutions in sectors like automotive and renewable energy. With these innovative technologies, extruded aluminum profiles are not just enhancing functionality but are also paving the way for environmentally friendly practices in manufacturing.