Aluminum Extrusion Tube Profiles offer unique benefits for various projects. Their lightweight nature makes them easy to handle and transport. These profiles are strong and durable, providing essential support in construction and manufacturing.

Using Aluminum Extrusion Tube Profiles, you can achieve intricate designs. They allow for precision in engineering. The versatility cannot be overlooked. From furniture to industrial applications, their adaptability shines through.

However, not every application sees success. Some may struggle with the cost compared to other materials. Reflecting on this can help project managers make informed decisions. Overall, Aluminum Extrusion Tube Profiles present many possibilities, but caution is recommended when selecting them for specific needs.

Aluminum extrusion tube profiles are increasingly popular in various industries. They offer several key benefits that can enhance project efficiency and effectiveness. For instance, according to a report by the Aluminum Association, aluminum is 100% recyclable. This aspect not only reduces waste but also lowers production costs for companies.

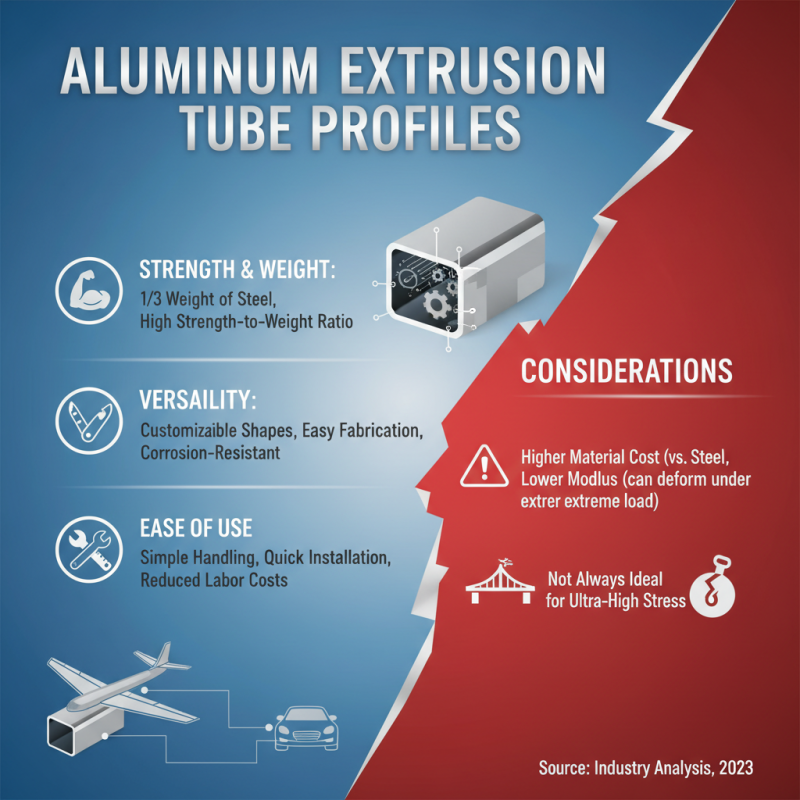

Moreover, aluminum's strength-to-weight ratio is exceptional. Extruded aluminum profiles are lightweight yet strong, making them ideal for structural applications. This advantage allows for easy transport and installation. In construction, for example, weight can significantly impact logistics. Projects that utilize aluminum can save on both time and money. However, some may find the initial investment in aluminum higher than other materials.

Additionally, aluminum tubes can be customized to fit specific needs. They can be extruded in various shapes, sizes, and lengths. This flexibility allows designers to create innovative solutions tailored to unique challenges. However, custom designs may require more upfront planning, which can be a hurdle for some teams. Overall, while aluminum extrusion tube profiles present undeniable advantages, careful consideration is essential when implementing them into projects.

Aluminum extrusion tube profiles are versatile components used in many industries. These profiles are lightweight and strong, making them ideal for various applications. In construction, they serve as framework supports for buildings and equipment. Their durability can withstand harsh environmental factors.

In the automotive industry, aluminum tubes reduce overall vehicle weight. This improves fuel efficiency. They are also used in manufacturing parts like chassis and heat exchangers. In electronics, these profiles are essential for housing components and protecting delicate equipment. However, one must consider their susceptibility to scratches and dents.

The packaging industry increasingly uses aluminum tube profiles. They are handy for creating containers that are lightweight yet sturdy. However, some designs may compromise structural integrity, requiring careful engineering. Additionally, not every design may meet the specific needs of all projects. Understanding the right application is critical for achieving optimal results.

Aluminum extrusion tube profiles are becoming a popular choice in various industries. They offer a balance of strength, weight, and versatility that is hard to beat. Compared to steel, aluminum is significantly lighter—up to one-third the weight. This property makes it easier to handle and install, especially in large-scale projects. However, while aluminum excels in many areas, it may not always be the ideal choice.

When analyzing aluminum against materials like PVC and stainless steel, each has its own advantages. PVC is less expensive but lacks the durability and heat resistance found in aluminum. Stainless steel offers greater strength but at a higher weight and cost. According to a report by the Aluminum Association, aluminum can have a lifecycle cost that is 30% lower than that of steel due to savings in transportation and installation.

Tips: Consider the application's specific requirements. Aluminum is corrosion-resistant, making it ideal for outdoor use. But in applications requiring extreme tensile strength, assess whether the weight advantage outweighs the strength deficit.

Another factor to reflect upon is recyclability. Aluminum can be recycled indefinitely without losing quality, whereas PVC and other plastics often degrade during recycling. This aspect may make aluminum a more sustainable choice in the long run. While aluminum seems attractive, it's crucial to evaluate the project’s unique needs thoroughly.

Aluminum extrusion tube profiles offer numerous advantages in manufacturing. One crucial process in their creation is the die design. A well-crafted die can significantly reduce waste and improve precision. According to a 2022 report by the Aluminum Association, efficient die design can boost productivity by up to 30%. The key lies in understanding the thermal and mechanical properties of aluminum during extrusion.

Next, the extrusion process itself involves heating aluminum billets to soften them. This allows for easier shaping through the die. A temperature range of 350-500°C is commonly used. This method fosters versatility in creating complex shapes. However, it can be an energy-intensive process. Industry estimates show that energy consumption can vary from 1.2 to 2.0 GJ per ton of extruded aluminum. Manufacturers face the challenge of balancing energy use and production efficiency.

Furthermore, the cooling stage plays a vital role. Rapid cooling can lead to better surface finish and mechanical properties. But, improper cooling techniques can result in warping or internal stresses. Maintaining consistent cooling rates requires careful monitoring. It's essential to reflect on these aspects to refine processes further. Continuous improvements in these manufacturing stages can drive quality and sustainability in aluminum extrusion.

When considering aluminum extrusion profiles for projects, several key factors come into play. The weight of aluminum is crucial. It is lightweight yet strong, making it ideal for various applications. This balance helps in reducing transportation costs. However, one must evaluate if the strength meets project requirements. Sometimes, lighter is not always better.

The finish of aluminum extrusions is another aspect to consider. Anodized surfaces offer enhanced corrosion resistance. This is particularly important in outdoor settings. Yet, not all finishes suit every environment. Choosing the wrong finish could lead to premature wear or aesthetic issues. It’s essential to reflect on specific project demands before deciding.

Furthermore, the design flexibility of aluminum extrusions is vital. These profiles can be customized to a wide range of shapes and sizes. This allows for innovative designs. However, this flexibility can also lead to over-complicated solutions. Balancing creativity with practicality is a challenge. Often, simpler designs can provide the most effective solutions. Engaging in this reflection can help streamline the project while reducing costs.