Aluminum extrusion profiles have become an indispensable component in various industries due to their remarkable versatility and strength-to-weight ratio. As per the latest report from the Aluminum Association, the global aluminum extrusion market is projected to reach approximately 25 million metric tons by 2025, driven by the increasing demand for lightweight materials in sectors such as automotive, construction, and aerospace. These profiles are produced through a specialized process that involves forcing aluminum alloy through a die, resulting in shapes and sizes tailored to specific applications.

The numerous applications of aluminum extrusion profiles highlight their significance in modern manufacturing. In the construction sector, for example, they are commonly used in window frames, railings, and structural components, thanks to their resistance to corrosion and ease of maintenance. Moreover, the automotive industry leverages these profiles for creating lightweight components that contribute to fuel efficiency and performance. With the growing emphasis on sustainability and energy efficiency, manufacturers are increasingly recognizing the benefits of aluminum extrusion profiles, including their recyclable nature and long lifespan, which align with eco-friendly practices and reduce overall material waste.

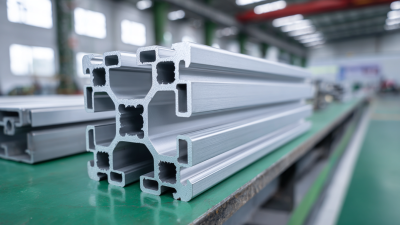

Aluminum extrusion profiles refer to the process by which raw aluminum material is transformed into objects with a defined cross-sectional shape. This is achieved through forcefully pushing the aluminum through a die, creating a continuous length of material that can be cut to various lengths. The result is lightweight, durable, and highly versatile profiles used in numerous applications, from construction frameworks to intricate electronic enclosures. The unique properties of aluminum, such as corrosion resistance and malleability, make it an ideal choice for extrusion.

The extrusion process begins with heating aluminum billets to a suitable temperature, allowing it to become more pliable. Once prepared, the aluminum is extruded through a die, which shapes it into the desired profile. After extrusion, the profiles are often cooled, stretched, and cut to meet specific requirements. This manufacturing technique enables the production of both standard and custom shapes, catering to diverse industries and applications. The efficiency of aluminum extrusion not only reduces material waste but also allows for high-speed production, making it a preferred method for crafting lightweight yet robust components.

The extrusion process begins with heating aluminum billets to a suitable temperature, allowing it to become more pliable. Once prepared, the aluminum is extruded through a die, which shapes it into the desired profile. After extrusion, the profiles are often cooled, stretched, and cut to meet specific requirements. This manufacturing technique enables the production of both standard and custom shapes, catering to diverse industries and applications. The efficiency of aluminum extrusion not only reduces material waste but also allows for high-speed production, making it a preferred method for crafting lightweight yet robust components.

Aluminum extrusion profiles are widely utilized across various industries due to their versatility and lightweight nature. One of the most prominent applications is in the construction sector, where they are used in window frames, doors, and structural components. The durability of aluminum ensures that these applications can withstand environmental stressors while maintaining aesthetic appeal. Additionally, aluminum profiles are employed in building facade systems, offering energy efficiency and reducing heat gain in buildings.

In the automotive industry, aluminum extrusion profiles are increasingly favored for lightweighting vehicles. By replacing heavier materials with aluminum, manufacturers can enhance fuel efficiency and reduce overall vehicle weight. Furthermore, these profiles play a vital role in creating heat exchangers and frames, contributing to better performance and safety. Other significant applications can be found in electronics, where aluminum extrusions serve as heat sinks and housings, effectively dissipating heat while providing structural integrity. From the aerospace sector to consumer products, the applications of aluminum extrusion profiles are extensive and continue to grow as industries seek more sustainable and efficient solutions.

Aluminum extrusion profiles offer a wide array of benefits that make them indispensable in construction and manufacturing industries. One primary advantage is their lightweight nature, which aids in reducing transportation costs by up to 30%, according to a report by the Aluminum Association. Additionally, aluminum has a high strength-to-weight ratio, providing robust structural integrity while enhancing efficiency. The corrosion resistance of aluminum means that structures require less maintenance over time, which can result in a 15-20% reduction in lifecycle costs, as highlighted in a recent sector study.

Another significant benefit is versatility. Aluminum extrusion profiles can be molded into complex shapes tailored to specific architectural and engineering requirements, allowing for innovative designs that can lead to energy savings of nearly 40% in heating and cooling. Moreover, these profiles can be recycled without loss of material quality, which is crucial for sustainability efforts in construction and manufacturing.

Tip: When choosing aluminum extrusion profiles for your project, consider not only the initial cost but also long-term savings on maintenance and energy efficiency.

Tip: Collaborate with extrusion manufacturers who offer customization options to ensure functionality meets aesthetic needs in your construction projects.

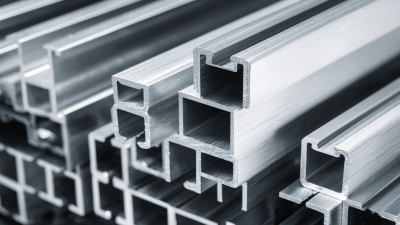

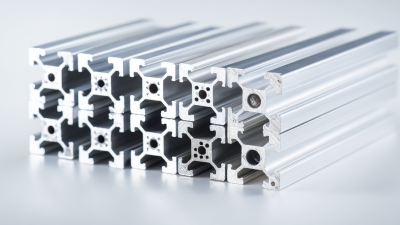

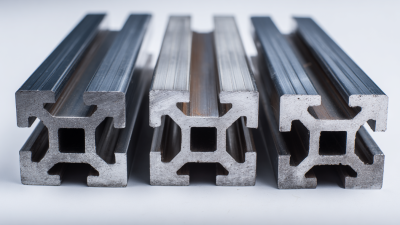

Aluminum extrusion profiles are versatile components utilized across various industries, thanks to their adaptability and strength. There are several types of extrusion profiles, each designed to meet specific requirements. Common varieties include structural beams, channels, and angles, which serve as the backbone of many architectural and engineering projects. Additionally, custom profiles can be engineered to meet unique specifications, catering to specialized applications in industries such as aerospace, automotive, and construction.

Another significant category is the decorative profiles, often used in interior design and furniture making. These profiles can enhance aesthetic appeal while providing functionality. Thermal break profiles are also essential in energy-efficient applications, helping to reduce heat loss in buildings. Overall, the diverse types of aluminum extrusion profiles allow for innovative designs and practical solutions across multiple sectors, highlighting their crucial role in modern manufacturing and construction practices.

| Type of Aluminum Extrusion Profile | Applications | Benefits | Common Materials Used |

|---|---|---|---|

| Structural Profiles | Construction, Building Frames | High strength-to-weight ratio, durability | 6061, 6063 Aluminum Alloys |

| Heat Sink Profiles | Electronics Cooling, LED Lighting | Efficient heat dissipation, lightweight | 6063, 6005 Alloys |

| Decorative Profiles | Interior Design, Furniture | Aesthetic appeal, corrosion resistance | 1050, 6060 Alloys |

| T-Slot Profiles | Modular Construction, Machinery | Versatile assembly, ease of use | 6063, 6082 Alloys |

| Angle Profiles | Support Structures, Bracing | Stability, rigidity | 6061, 6063 Alloys |

The realm of aluminum extrusion profiles is continually evolving, driven by innovative trends that enhance their applications across various industries. One of the most significant advancements is the integration of smart technologies into aluminum profiles. This involves embedding sensors and IoT devices within the profiles, allowing for real-time monitoring and improved safety features in construction and transportation. These smart aluminum profiles not only contribute to enhanced performance but also drive energy efficiency and sustainability in building designs.

Moreover, the demand for lightweight yet robust materials is pushing the boundaries of aluminum extrusion. Industries such as aerospace and automotive are increasingly adopting advanced aluminum alloys and custom profiles that reduce weight while maintaining structural integrity. This shift not only aids in fuel efficiency but also aligns with global sustainability goals. As manufacturers explore new techniques such as 3D printing and hybrid materials, the future of aluminum extrusion profiles promises even greater versatility, catering to the specific needs of diverse applications while minimizing environmental impact.