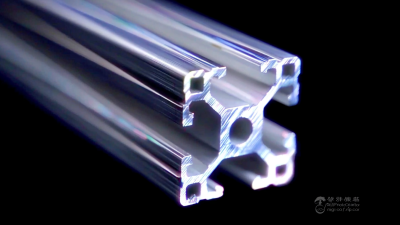

In today's rapidly evolving manufacturing landscape, the pursuit of sustainability has become paramount, and one pivotal solution stands out:

Aluminum Extrusion. Renowned expert Dr. Emily Carter, a leader in sustainable materials science, emphasizes the transformative potential of this process by stating,

"Aluminum Extrusion not only reduces waste but also enhances the lifecycle of products, making it an indispensable part of sustainable manufacturing."

As industries strive to decrease their carbon footprints and embrace eco-friendly practices,

Aluminum Extrusion emerges as a key player. This versatile technique offers the ability to create lightweight yet durable components, significantly impacting sectors ranging from

automotive to construction. By adopting Aluminum Extrusion, manufacturers can leverage materials that are 100% recyclable,

thereby contributing to a circular economy.

The shift towards sustainable practices is not merely a trend; it represents a fundamental change in how products are designed and produced.

With leaders like Dr. Carter advocating for the integration of innovative manufacturing techniques, the future of Aluminum Extrusion is bright.

This method not only aligns with global sustainability goals but also propels the growth of responsible production practices,

ensuring a better tomorrow for industry and the planet alike.

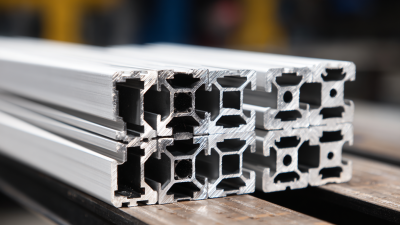

Aluminum extrusion plays a pivotal role in sustainable manufacturing, primarily due to its low environmental impact compared to traditional manufacturing processes. The extrusion process allows for the efficient use of aluminum, a material that is both lightweight and recyclable. By using aluminum, manufacturers can minimize resource consumption and energy use during production. The ability to create complex shapes with precision also means that less material is wasted, contributing to a more sustainable production cycle.

Furthermore, aluminum's recyclability significantly enhances its environmental credentials. Unlike some materials that degrade in quality after recycling, aluminum maintains its properties, allowing it to be reused indefinitely. This closed-loop system not only reduces the need for raw materials but also lowers the carbon footprint associated with the production process. As industries strive to meet stricter environmental regulations and consumer demand for greener products, aluminum extrusion stands out as a viable solution that mitigates negative impacts on the environment while supporting sustainable manufacturing growth.

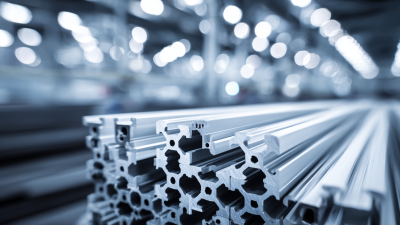

Innovative aluminum extrusion techniques are at the forefront of enhancing energy efficiency in manufacturing processes. According to a report by the Aluminum Association, aluminum weighs about one-third of steel while retaining comparable strength, leading to reduced energy consumption during transportation and product use. The lightweight nature of extruded aluminum components contributes significantly to fuel savings in both automotive and aerospace sectors. For instance, a study by the U.S. Department of Energy suggests that utilizing lightweight materials in vehicles can improve fuel economy by 6-8% for every 10% reduction in weight, underscoring the importance of aluminum in achieving sustainable manufacturing goals.

Moreover, advancements in extrusion technology, such as optimized die designs and automated production processes, further enhance the energy efficiency of aluminum manufacturing. According to data from the International Aluminum Institute, these innovations can lead to a 25% reduction in energy consumption during the extrusion process itself. Additionally, using recycled aluminum for extrusion can save up to 95% of the energy needed to create new aluminum from bauxite ore. These statistics highlight how innovative aluminum extrusion techniques not only drive energy efficiency but also promote overall sustainability in the manufacturing industry, making aluminum a vital material for the future.

Aluminum extrusion has emerged as a cornerstone for sustainable manufacturing, providing significant economic benefits that align with environmental goals. According to a report by the Aluminum Association, the recycling rate of aluminum is approximately 75%, which is substantially higher than many other materials. This high recyclability not only ensures reduced raw material costs but also supports a circular economy, minimizing waste and energy consumption during production. Companies utilizing aluminum extrusion can lower their carbon footprint, which is becoming increasingly important in a market that prioritizes sustainability.

**Tip:** When considering aluminum extrusion for your manufacturing needs, evaluate suppliers based on their recycling processes and sustainability certifications. This will ensure that your production aligns with eco-friendly practices and may enhance your brand’s reputation.

In addition to environmental advantages, aluminum extrusion is economically beneficial. A study by the International Aluminum Institute indicates that aluminum can save manufacturers up to 50% in energy costs compared to steel. The versatility of aluminum also allows for lightweight designs, which can lead to decreased transportation costs and enhanced product performance. By investing in aluminum extrusion, businesses can not only achieve sustainability goals but also improve their bottom line.

**Tip:** Explore partnerships with local recycling firms to ensure a steady supply of recycled aluminum, potentially lowering material costs while contributing to sustainable practices.

The successful implementation of aluminum extrusion in green manufacturing is exemplified by several case studies that highlight its environmental and economic benefits. One notable example is a leading automotive manufacturer that adopted aluminum extrusion to create lightweight vehicle components. This shift not only reduced the overall weight of their vehicles but also enhanced fuel efficiency, thereby lowering carbon emissions. The company reported a significant decrease in energy consumption during the production process, showcasing how aluminum extrusion can support sustainable practices while meeting market demands.

Another compelling case involves a construction firm that utilized aluminum extrusions for eco-friendly building facades and structural elements. By leveraging aluminum's recyclability and longevity, the firm was able to design structures that minimize waste and reduce the need for frequent replacements. The project not only resulted in lower lifecycle costs but also garnered recognition for its commitment to sustainability. These examples illustrate how aluminum extrusion is not just a manufacturing technique but a critical component of sustainable growth strategies across various industries.

Aluminum extrusion is increasingly recognized as a cornerstone for sustainable manufacturing growth. As industries seek to minimize their environmental impact, aluminum's recyclability and lightweight properties make it an ideal choice for various applications. Future trends indicate that advancements in extrusion technology are not only enhancing efficiency but also broadening the scope of aluminum's use in innovative products. By integrating smart manufacturing techniques and investing in renewable energy sources, companies can further elevate the sustainability of their operations.

Aluminum extrusion is increasingly recognized as a cornerstone for sustainable manufacturing growth. As industries seek to minimize their environmental impact, aluminum's recyclability and lightweight properties make it an ideal choice for various applications. Future trends indicate that advancements in extrusion technology are not only enhancing efficiency but also broadening the scope of aluminum's use in innovative products. By integrating smart manufacturing techniques and investing in renewable energy sources, companies can further elevate the sustainability of their operations.

Tips: Embrace automation in your extrusion processes. Implementing automated systems can significantly reduce waste and improve production efficiency while allowing for better energy management. Moreover, keep an eye on developments in aluminum alloys, as new materials can optimize performance and sustainability in your products.

The push for circular manufacturing is another trend shaping the future of aluminum extrusion. Companies are increasingly focusing on closed-loop recycling systems, which not only lower raw material costs but also minimize carbon footprints. By collaborating with suppliers and promoting recycling initiatives, manufacturers can create a more sustainable supply chain, ultimately contributing to longer-lasting industrial growth.

Tips: Foster partnerships with recycling companies to streamline your material recovery processes. This collaboration can enhance your sustainability strategy and open up new business opportunities through resource sharing and innovation.