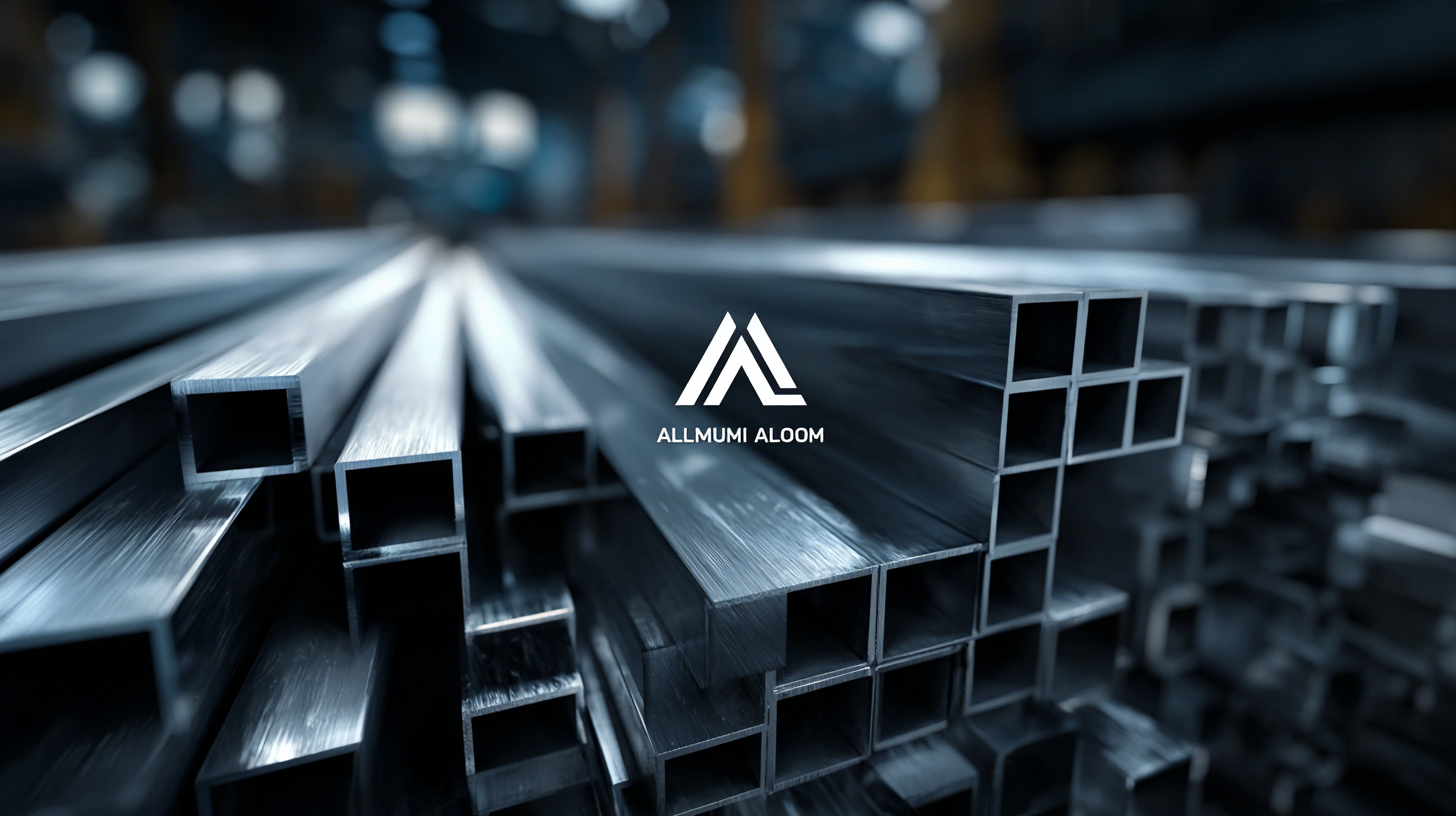

In the ever-evolving landscape of industrial materials, Aluminum Alloy Profiles have emerged as a preferred choice for global buyers seeking durability, versatility, and aesthetic appeal. These high-performance profiles not only contribute to the structural integrity of various applications but also offer significant advantages in terms of weight reduction and corrosion resistance. As industries demand more innovative and sustainable solutions, premium Aluminum Alloy Profiles stand out by delivering exceptional quality and adaptability, making them ideal for sectors ranging from construction to automotive. This blog aims to unveil the numerous benefits that come with investing in these profiles, highlighting how they can provide right solutions tailored to diverse needs, and ultimately enriching the end user's experience.

Premium aluminum alloy profiles offer significant advantages for global buyers, positioning them as optimal choices for a variety of applications across different industries. According to a report by the Aluminum Association, the demand for aluminum products is expected to increase by approximately 25% over the next five years due to their superior strength-to-weight ratio, corrosion resistance, and recyclability. These profiles are not only lightweight but also durable, making them ideal for sectors such as construction, automotive, and aerospace, where performance is critical.

Moreover, premium aluminum alloys can be tailored to meet specific requirements, enhancing their versatility. The global market for aluminum profiles is projected to reach over $100 billion by 2026, driven by advancements in alloy technology that allow for greater customization in fabrication processes. This flexibility enables manufacturers to create components that align perfectly with design specifications while maintaining structural integrity. The ability to innovate with aluminum alloys is further supported by ongoing investments in research and development, ensuring that global buyers continue to reap the benefits of cutting-edge materials that meet the evolving demands of various markets.

The demand for aluminum alloy profiles is witnessing significant growth across various key industries, driven by their unique characteristics such as lightweight, high strength, and recyclability. The North American soft alloy aluminum extrusion market is expected to reach USD 6.79 billion in 2023, with a robust growth trajectory projected at a CAGR of 7.1% through 2030. This upward trend highlights the increasing reliance on aluminum alloy profiles in sectors ranging from automotive to construction, where efficiency and sustainability are paramount.

Additionally, the global aluminum wire rod market, valued at $22.6 billion in 2023, is set to expand, fueled by the rising consumption patterns and evolving market dynamics. The versatility of aluminum alloys makes them the preferred choice in manufacturing applications, particularly as innovations in high-strength aluminum alloys continue to emerge. With an anticipated market value of $84.4 billion by 2030, the strategic shift towards these materials underscores a growing commitment to lightweight solutions and the circular economy in manufacturing processes worldwide.

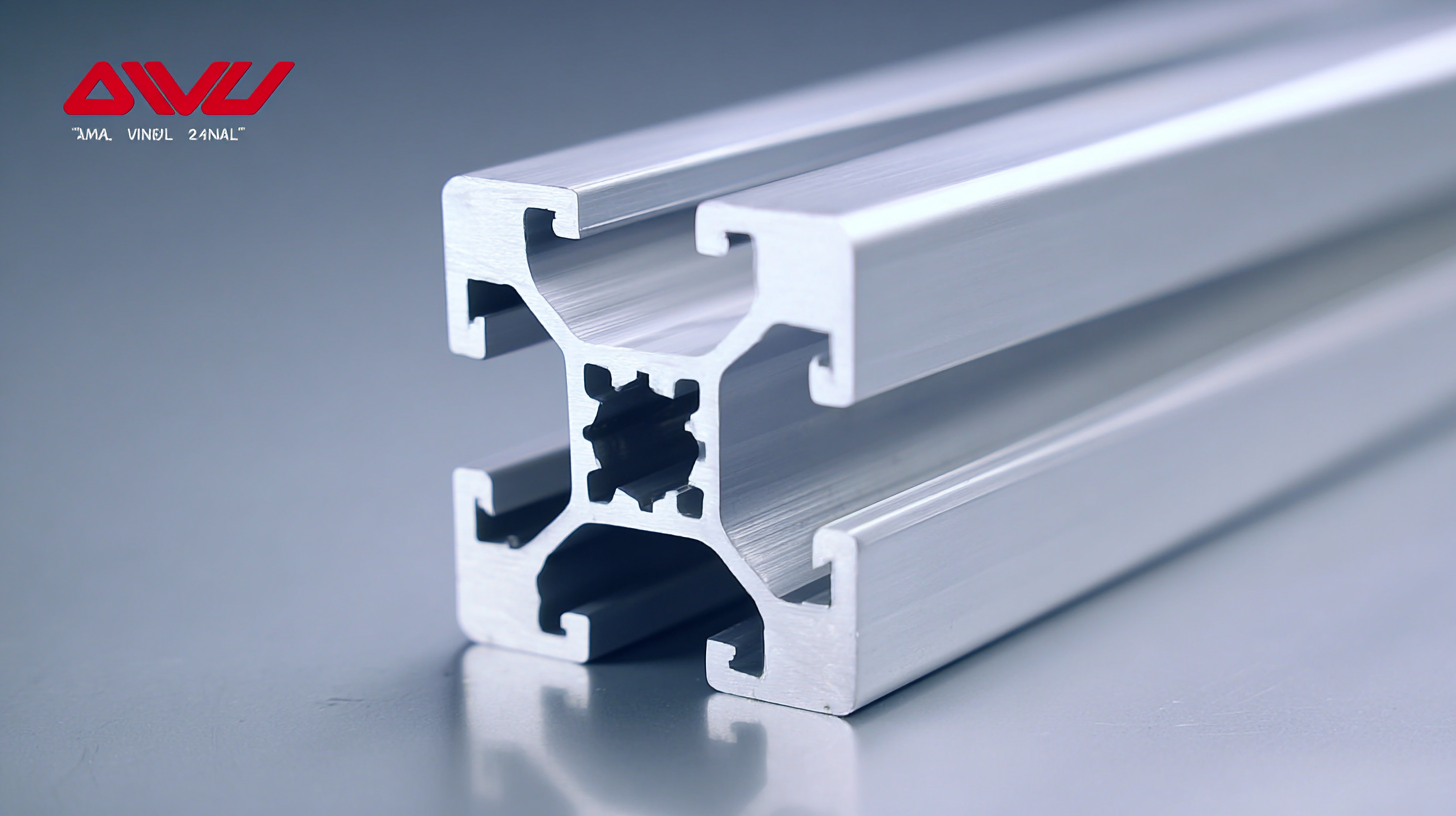

Premium aluminum alloy profiles are becoming increasingly favored across various industries due to their superior performance characteristics compared to standard alternatives. According to a report by the Aluminum Association, premium alloys exhibit a tensile strength that can be up to 50% greater than standard alloys, enabling them to withstand more demanding applications without compromising on weight. This advantage makes them ideal for sectors such as aerospace and automotive, where performance and safety are paramount.

In addition to strength, premium aluminum alloys offer enhanced corrosion resistance, which is critical for longevity in harsh environments. A study published by the International Journal of Materials Science states that the precise composition and treatment of premium alloys can result in a lifespan that extends beyond 20 years under extreme conditions, significantly reducing maintenance costs. Furthermore, their excellent thermal conductivity, with values reaching up to 205 W/m·K, facilitates better energy efficiency in applications like evaporators and heat exchangers, differentiating them from standard profiles typically averaging around 130 W/m·K. This combination of durability and efficiency makes premium aluminum alloys an essential choice for global buyers seeking long-term value.

When considering investments in aluminum profiles, a cost-benefit analysis reveals that opting for

premium aluminum alloy profiles can significantly enhance

value over time. According to a report by the Aluminum Association, high-quality aluminum profiles can yield

a lifespan increase of 25% compared to standard options.

This extended longevity reduces the frequency of replacements, ultimately decreasing costs associated with

repairs and material waste.

Tip: Before making a purchase, evaluate the tensile strength and corrosion resistance of

the aluminum profiles. A stronger alloy not only

lasts longer but also minimizes maintenance costs.

Furthermore, premium aluminum profiles can offer improved aesthetics and functionality, which is

crucial in industries where appearance and performance are paramount. A study by Research and Markets

highlights that premium profiles contribute to energy efficiency

in buildings by enhancing thermal insulation, leading to energy savings of up to 30%

annually. This can drastically lower operating costs over the lifecycle of the building.

Tip: Look for suppliers that provide detailed specifications and certifications of

their aluminum profiles to ensure you are investing in products that meet industry standards for

quality and efficiency.

The increasing emphasis on sustainability within various industries has brought premium aluminum alloy profiles to the forefront of eco-friendly building materials. Aluminum alloys are inherently recyclable, with the capability to be reused multiple times without losing their intrinsic properties. This recyclability significantly reduces the energy and resources required for producing new materials, making aluminum alloys a preferred choice for global buyers seeking to minimize their environmental impact.

Moreover, the lightweight nature of aluminum alloys leads to energy savings during transportation and installation. Structures made from these profiles not only consume less energy in their construction phase but also contribute to decreased energy requirements throughout their lifespan. With rising global concerns over carbon emissions and resource depletion, adopting aluminum alloys represents a proactive approach for companies looking to align their operations with sustainable practices. By choosing premium aluminum alloy profiles, businesses not only enhance their product offerings but also take a meaningful step towards environmental stewardship.