In today's competitive market, businesses are increasingly recognizing the vital role that high-quality Aluminum Profiles play in enhancing operational efficiency and product performance. As reported by the Aluminum Association, the demand for aluminum products is projected to grow by 4.4% annually over the next five years, driven by the material’s lightweight properties and outstanding durability. Moreover, the International Aluminum Institute highlights that the use of aluminum in various industries can reduce energy consumption by up to 30%. These statistics underscore the significance of leveraging advanced aluminum profiles in manufacturing and construction sectors. By unlocking the advantages of these profiles, businesses can achieve lower production costs, improved sustainability, and greater design flexibility. This blog will explore top strategies for effectively incorporating high-quality aluminum profiles into your business operations, ensuring you stay ahead in a rapidly evolving landscape.

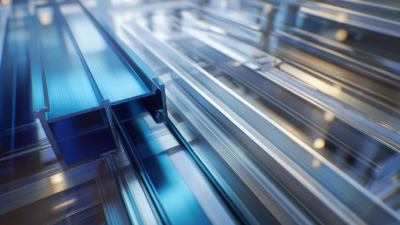

When it comes to aluminum profile manufacturing, quality should never be compromised.

High-quality aluminum profiles play a pivotal role in the overall performance and longevity of various applications, from construction to automotive and electronics.

Businesses that prioritize quality in their sourcing decisions often find that their products showcase superior durability,

aesthetic appeal, and precision. This ensures not only customer satisfaction but also helps in building a reputable brand image in a competitive market.

The manufacturing process of aluminum profiles involves intricate techniques that require adherence to strict quality standards.

Failing to focus on quality can lead to defects, which may result in increased costs due to wasted materials and resources.

Moreover, poor-quality profiles can jeopardize safety in construction applications or cause inefficiencies in machinery operations.

Therefore, embracing high-quality aluminum profiles allows businesses to mitigate these risks, ensuring that their products perform optimally while also complying with industry regulations.

By investing in quality manufacturing, companies can secure a reliable supply chain, enhance operational efficiency, and ultimately drive long-term success.

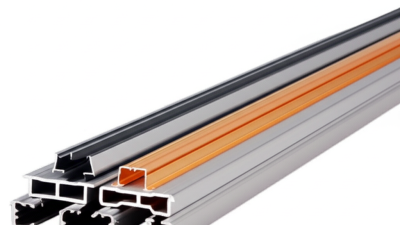

High-quality aluminum profiles are becoming increasingly vital across various industries, thanks to their exceptional strength-to-weight ratio, corrosion resistance, and versatility. According to a report by Research and Markets, the global aluminum profile market is expected to grow at a CAGR of 5.6%, reaching approximately $70 billion by 2026. One of the primary applications of these profiles is found in the construction sector, where they are used in window frames, curtain walls, and facades. Their lightweight nature aids in reducing transportation costs and simplifying installation processes while maintaining structural integrity.

In the automotive industry, high-quality aluminum profiles contribute to building lighter vehicles, which enhances fuel efficiency and reduces emissions. The Lightweighting Technology Report indicates that for every 10% reduction in vehicle weight, fuel efficiency can improve by 6-8%. Furthermore, the use of aluminum in electric vehicles (EVs) is on the rise, as manufacturers increasingly prioritize lightweight materials to extend battery life and enhance performance. The electronic and consumer goods sectors also benefit from aluminum's aesthetic potential, enabling sleek product designs while ensuring durability and functionality. As these applications continue to expand, investing in high-quality aluminum profiles can significantly boost operational efficiency and product appeal in diverse markets.

| Industry | Application | Benefits of Aluminum Profiles | Typical Uses |

|---|---|---|---|

| Construction | Windows and Doors | Durability, corrosion resistance | Residential and commercial buildings |

| Automotive | Chassis and Body Components | Lightweight, enhances fuel efficiency | Cars, trucks, and vehicles |

| Aerospace | Aircraft Frames | Strength to weight ratio | Commercial and military aircraft |

| Electronics | Heat Sinks | Excellent thermal conductivity | Computers and mobile devices |

| Furniture | Frames and Supports | Stylish, modern designs | Office and home furniture |

When considering the investment in aluminum profiles, businesses often overlook the long-term cost-effectiveness of choosing high-quality solutions. According to the Aluminum Association’s 2021 Industry Report, premium aluminum profiles can reduce lifecycle costs by nearly 30%. This is primarily attributed to their superior durability and resistance to corrosion, which minimizes maintenance expenses and extends the overall lifespan of products. For instance, businesses in the construction and manufacturing sectors report decreased replacement rates of up to 40% when utilizing high-grade aluminum profiles compared to standard offerings.

Moreover, the initial investment in premium aluminum profiles is offset by the increased efficiency they offer in production and design versatility. A survey by Research and Markets found that companies employing high-quality aluminum profiles experienced a productivity boost of approximately 15%, as these profiles facilitate faster assembly processes and allow for more innovative design applications. Thus, despite a higher upfront cost, the strategic choice of investing in premium aluminum profiles ultimately enhances operational efficiency and long-term financial savings for businesses across various industries.

This chart illustrates the cost-effectiveness of investing in premium aluminum profile solutions compared to standard alternatives. The values represent the average lifespan (years), maintenance costs ($/year), and initial investment ($) for both types of profiles.

Sustainable aluminum profiles offer significant environmental benefits that set them apart in the manufacturing industry. One of the key advantages is their recyclability. Aluminum can be recycled repeatedly without losing its integrity or quality, making it an ideal choice for businesses looking to minimize waste. This not only reduces the demand for virgin materials but also conserves energy, as recycling aluminum requires up to 95% less energy compared to producing new aluminum from ore.

Moreover, using high-quality sustainable aluminum profiles helps reduce the overall carbon footprint of products. These profiles are often manufactured using eco-friendly processes that emit fewer pollutants into the atmosphere. When businesses adopt sustainable materials, they contribute to a circular economy, where products are designed with their entire lifecycle in mind. This shift not only improves corporate responsibility but also appeals to environmentally conscious consumers, aligning with their values and preferences for sustainable practices. By choosing high-quality aluminum profiles, businesses can enhance their environmental performance while gaining a competitive edge in the marketplace.

The future of aluminum profile technology is poised for significant advancements, driven by increasing demand across various industries. According to a recent market report by ResearchAndMarkets, the global aluminum profiles market is expected to reach $100 billion by 2026, growing at a CAGR of 6% from 2021. This growth is primarily fueled by the automotive, construction, and aerospace sectors, which emphasize lightweight materials for improved energy efficiency and performance. Companies utilizing high-quality aluminum profiles can enhance their product offerings and compete more effectively in these evolving markets.

Technological innovations, such as the integration of smart manufacturing and additive manufacturing techniques, are reshaping the aluminum profile industry. Companies are now able to produce custom profiles with improved strength and reduced weight, catering to specific business needs. Additionally, the implementation of sustainable practices, like recycling aluminum and reducing waste, not only supports environmental goals but also appeals to increasingly eco-conscious consumers. As businesses adopt these trends, high-quality aluminum profiles will become a key differentiator, contributing to both operational efficiency and brand reputation.