In the world of manufacturing, Channel Aluminum Extrusion Profiles play a crucial role. These profiles are essential for a variety of applications, from construction to automotive industries. They offer lightweight strength and versatility, making them a popular choice.

Selecting the right Channel Aluminum Extrusion Profiles can be complex. There are many options to consider. Each profile serves unique purposes. Understanding these options helps in making informed decisions. However, this knowledge often comes with challenges. Not every profile will suit every project.

In this guide, we explore the top Channel Aluminum Extrusion Profiles for 2026. We aim to highlight their applications and benefits. You may face unexpected hurdles when choosing the right profile. This journey provides insights into navigating those choices.

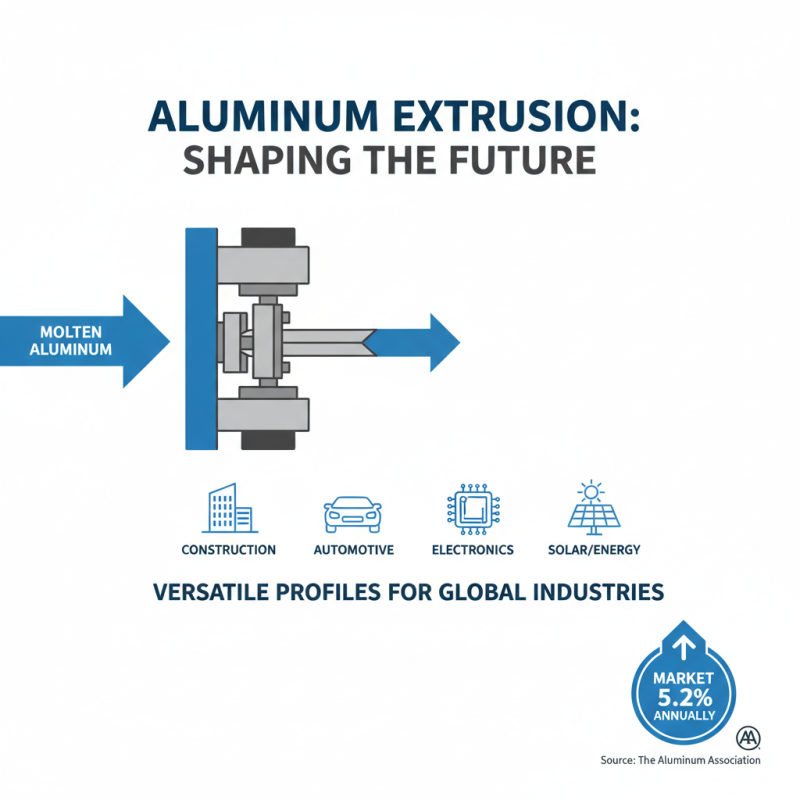

Aluminum extrusion is a vital manufacturing process. It involves creating shapes by forcing aluminum through a die. The result is versatile profiles used in various industries. According to a report by the Aluminum Association, the global aluminum extrusion market is expected to grow by 5.2% annually.

Understanding the basics of aluminum extrusion can enhance efficiency. The process allows for complex shapes with tight tolerances. Heat treatment further improves strength and durability. Notably, this material is lightweight and resistant to corrosion. However, not all extrusion products are created equal. Some profiles may lack the necessary structural integrity for demanding applications.

Another key benefit is the sustainability of aluminum. Roughly 75% of aluminum produced in the last 100 years is still in use today. Recycling aluminum saves 95% of the energy needed to create new aluminum. Despite these advantages, businesses must ensure proper design and manufacturing processes. Poorly designed profiles can lead to failure in crucial settings. Therefore, comprehensive understanding and careful planning are essential.

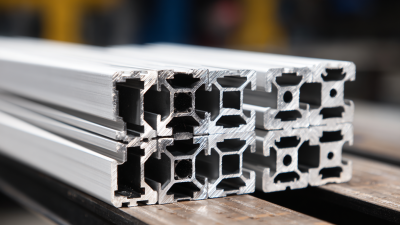

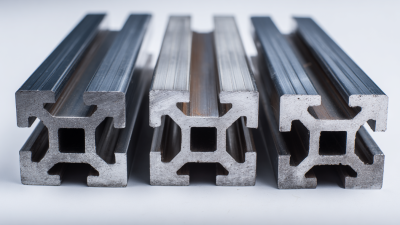

Channel aluminum extrusion profiles are versatile and widely used in various applications. These profiles come in different designs, each tailored for specific needs. Common types include U-channels, Z-channels, and C-channels.

U-channels offer open sides, making them ideal for mounting panels. Z-channels provide stability and are often used in framing applications. C-channels are great for creating supports in construction.

Each type of channel profile serves unique functions. For example, U-channels are excellent for structural reinforcements. They help create strong yet lightweight frameworks. However, not every channel profile is suited for every application. The weight load and environmental factors should always be considered. Failing to do so may lead to structural failures. It’s essential to match the profile design with the intended use carefully.

Moreover, users might overlook the importance of proper finishing. Unfinished edges can corrode and weaken the profile over time. Anodizing or powder coating can enhance durability. Yet, these options increase costs. Striking a balance between durability and budget can be challenging. Ultimately, understanding each channel profile's purpose can lead to better selection and application.

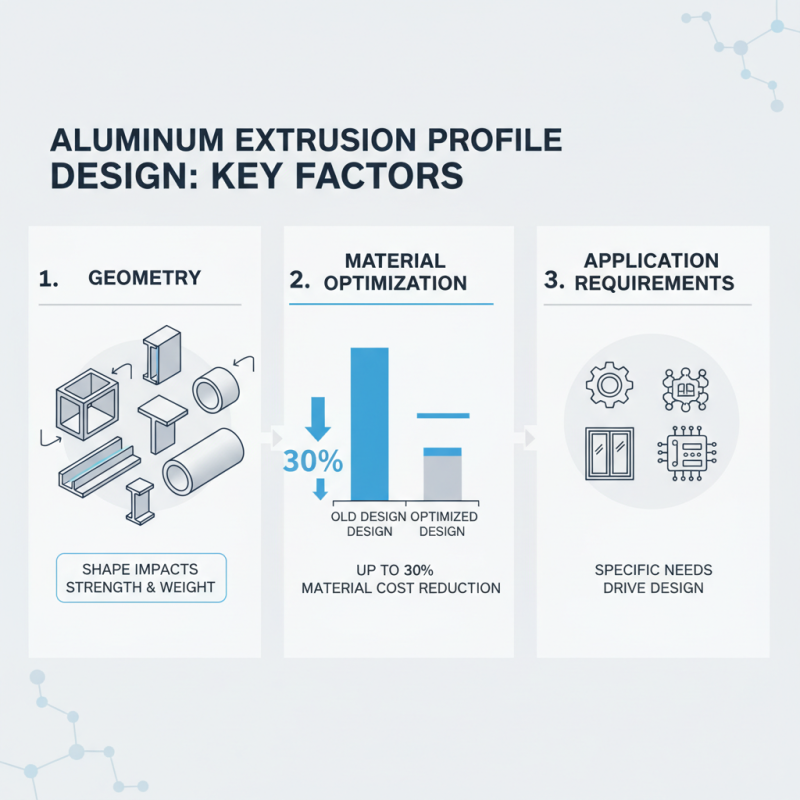

When designing aluminum extrusion profiles, several key factors must be considered. The geometry of the profile is crucial. Different shapes can impact the strength and weight of the extrusion. According to a recent industry report, a well-optimized profile can reduce material costs by up to 30%. This highlights the importance of understanding the specific requirements of each application.

Another critical aspect is the manufacturing process. The extrusion temperature and die design directly influence the mechanical properties of the final product. A study has shown that slight variations in temperature can lead to differences in hardness and tensile strength. This inconsistency can pose challenges for manufacturers focused on quality control.

Additionally, surface finish plays a vital role. A good finish can enhance corrosion resistance and aesthetics. However, achieving the perfect balance between finish and functionality is often tricky. Reports indicate that around 15% of extrusions fail quality checks due to surface imperfections. This highlights the need for continuous improvement in design and production methods.

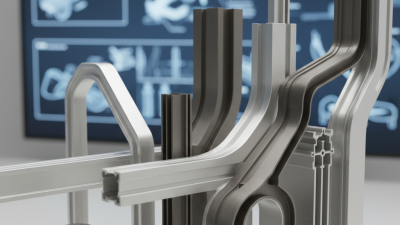

Aluminum extrusion is a fascinating manufacturing process. It transforms raw aluminum into specific shapes for various applications. The process begins with heating aluminum billets until they become malleable. This stage is crucial, as improperly heated aluminum can lead to defects. After heating, the softened material is pushed through a die to create the desired profile.

There are various extrusion methods, including direct and indirect extrusion. Direct extrusion pushes the billet directly through the die. It’s efficient but can create defects if not handled properly. Indirect extrusion, on the other hand, is more complex but can yield better surface finishes. Both methods have their pros and cons. Many manufacturers prefer one over the other, but personal experience can influence that choice.

Quality control plays a significant role in the extrusion process. Minor flaws in temperature or timing can lead to imperfections in the final product. It's essential to monitor these variables closely to achieve high-quality results. Yet, not all manufacturers prioritize this aspect. Some overlook it, leading to higher rejection rates. Reflecting on these issues in aluminum extrusion can significantly impact production effectiveness.

| Profile Type | Dimensions (mm) | Weight (kg/m) | Applications |

|---|---|---|---|

| U-Channel | 50 x 25 | 1.58 | Frameworks, support structures |

| C-Channel | 75 x 40 | 2.47 | Railings, machine parts |

| Z-Channel | 60 x 40 | 2.80 | Industrial shelving, supports |

| Rectangular Tube | 40 x 20 | 1.44 | Furniture, frames |

| Square Tube | 30 x 30 | 1.06 | Constructions, enclosures |

The future of aluminum extrusion is evolving, driven by sustainability. Industry reports show that over 75% of aluminum used today is recycled. This trend is crucial for reducing greenhouse emissions. The global aluminum extrusion market is projected to grow significantly by 2026, with a rising emphasis on eco-friendly practices.

Innovative projects highlight the importance of using energy-efficient methods in production. Companies are adopting advanced technology that lowers energy consumption by 20%. This shift not only cuts costs but also minimizes environmental impact. Recycling efforts are being intensified. It’s estimated that utilizing recycled aluminum saves 95% energy compared to primary production.

**Tip:** Always choose recycled aluminum for your projects. It benefits both the environment and your budget.

While progress is being made, challenges remain. Some manufacturers struggle to adopt sustainable practices fully. The initial costs can be high, causing hesitation. Continuous education and investments are vital in pushing the industry forward. Aligning with green standards can be a driving force for innovation and market growth.

**Tip:** Evaluate suppliers for their sustainability commitments. Take time to research their practices. It's worth the effort.