In the dynamic world of Aluminum Alloy Profiles, innovation is paramount. As we look ahead to 2026, experts foresee significant trends shaping the industry. John Doe, a leading authority in the field, once stated, “The future of Aluminum Alloy Profiles lies in adaptability and sustainability.” His insight reflects the growing demand for eco-friendly materials and innovative designs.

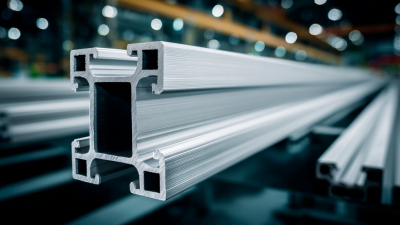

The Aluminum Alloy Profiles sector is undergoing transformative changes. Manufacturers are focusing on lightweight, durable products to meet various industry needs. This shift aims to improve efficiency while reducing environmental impact. With sustainability at the forefront, companies are also investing in advanced technologies. These developments enhance production processes and product performance.

However, challenges remain. The industry's reliance on certain materials can hinder innovation. Companies must rethink their approaches to sourcing and manufacturing. The journey toward better Aluminum Alloy Profiles requires continuous improvement. Addressing these challenges will be vital for future success.

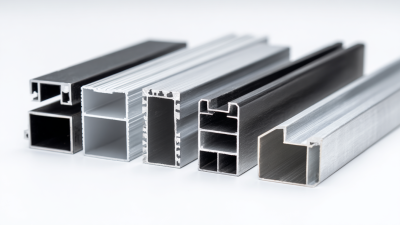

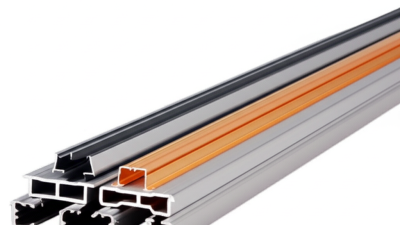

The landscape of aluminum alloy profiles is evolving rapidly. By 2026, we expect innovative designs that improve strength and reduce weight. The focus will shift towards sustainability, with recyclable materials becoming a priority. Many designers are experimenting with shapes that enhance performance in structural applications. Customized solutions may replace standard offerings.

Tip: Always consider the weight-to-strength ratio when selecting materials. It plays an essential role in overall design efficiency.

Aesthetic designs will also gain traction. People want functional elements that appeal visually. Color anodization and brushed finishes offer unique looks. However, balancing aesthetics and performance can be tricky. It's essential to remember that not all beautiful designs hold up under pressure.

Tip: Collaborate with engineers early in the design process. Their insights can help refine your projects. It's a way to avoid the pitfalls of purely aesthetic choices.

Innovative manufacturing techniques are transforming the aluminum profiles industry. These methods aim to enhance efficiency and reduce costs. For instance, additive manufacturing is gaining traction. It allows for complex shapes and reduces waste significantly. Manufacturers can create intricate designs that were previously difficult to achieve.

New alloys are also being developed. These blends enhance durability and resistance to corrosion. There is a focus on lightweight solutions. This is crucial for industries like automotive and aerospace. Yet, challenges remain. The balance between strength and weight is delicate. Innovations in machining processes are evolving too. They improve precision and shorten production times.

Despite these advancements, not all techniques are universally applicable. Some may only work for specific profiles or applications. There’s room for improvement in energy efficiency as well. Environmental considerations are becoming increasingly important. As the industry evolves, a reflective approach is necessary.

The aluminum alloy industry is increasingly prioritizing sustainability. Production methods are evolving to reduce energy consumption. Innovations in recycling processes are also emerging, aiming to minimize waste. Closed-loop recycling systems are gaining traction. This ensures that discarded aluminum can efficiently be repurposed for new products.

Recycling aluminum alloys saves significant energy compared to primary production. Yet, the overall recycling rate remains far from perfect. Many alloys are still disposed of improperly. This is a problem that needs urgent attention. Education on proper recycling methods is crucial for improvement.

Sustainable practices can be enhanced through collaborations. Industries must work together to share best practices. Investments in technology could lead to breakthroughs in recycling efficiency. Awareness campaigns could inspire better public participation in recycling initiatives. A shift in mindset is needed for meaningful change in aluminum alloy production and recycling.

The aluminum alloy sector is witnessing significant change. Emerging applications across various industries are driving this evolution. The automotive industry, for instance, looks to aluminum alloys for lighter vehicles. This shift aims to improve fuel efficiency. According to the Aluminum Association, lightweight structures can achieve up to 30% weight reduction. This is critical for manufacturers racing to meet environmental regulations.

Moreover, the aerospace segment is also evolving. Advanced aluminum alloys assist in building fuel-efficient aircraft. Reports show that the use of aluminum reduces weight without compromising strength. The International Air Transport Association estimates that a 1% reduction in weight can save millions in fuel costs annually. However, the challenges persist. Not every alloy can withstand extreme conditions. Finding that balance between durability and weight remains daunting.

Construction is tapping into aluminum alloys for their sustainability. Nearly 50% of the North American construction market is adopting aluminum. Its recyclability offers long-term benefits. Despite this growth, manufacturers face obstacles in scaling production. Many struggle to meet increasing demand while ensuring quality. As the industry evolves, continuous innovation and adaptation are essential.

| Application Area | Aluminum Alloy Type | Key Features | Market Growth Rate (2026) | Main Benefits |

|---|---|---|---|---|

| Automotive | 6061 | Corrosion resistance, weldability | 7% | Lightweight, fuel efficiency |

| Aerospace | 2024 | High strength-to-weight ratio | 5% | Improved performance, fuel savings |

| Construction | 6063 | Extrudability, surface finish | 6% | Versatility, aesthetic appeal |

| Consumer Electronics | 5052 | Excellent corrosion resistance | 8% | Durability, modern design |

| Packaging | 8011 | Stiffness, lightweight | 4% | Recyclable, cost-effective |

The aluminum alloy market is witnessing significant growth. Demand for lightweight and durable materials is rising across various industries. This trend is particularly evident in aerospace and automotive sectors, where efficiency is crucial. These industries are pushing for innovations in aluminum alloy profiles. New applications are emerging, driven by the need for sustainability and better performance.

Investments in research and development are crucial for future growth. Innovations focus on enhancing properties like strength and corrosion resistance. Manufacturers are exploring new alloys and production techniques. However, challenges persist. Cost management and supply chain issues can hinder progress. Some smaller companies struggle to keep up, highlighting market disparities.

As we move toward 2026, understanding market dynamics will be key. Consumer preferences are evolving, influencing demand patterns. The push for greener technologies may also shift the landscape. Companies must adapt and innovate to stay relevant. Staying alert to these trends is essential for future success.